Caring for your central heating

Your Barratt home is fitted with an efficient central heating system. With a little bit of care and attention it should keep you cosy for many years to come.

The first thing you’ll need to do is identify what kind of heating system you have in your home.

Air source heat pump

Servicing an air source heat pump

Regular Servicing will ensure your system keeps running effectively and efficiently and can solve any issues before they cause a breakdown.

You should arrange for your air source heat pump to be serviced annually and in accordance with the manufacturers recommendations. Servicing should be completed by an installer or the manufacturer.

A well maintained heating system will ensure you are getting the best performance from your heat pump. Please note that annual servicing is also a requirement to maintain our 2 year warranty on your heating system.

Conventional boiler system

Servicing a conventional boiler

Condensing boilers are extremely reliable, but must still be serviced every year by a Gas Safe-registered engineer.

It’s important to have an annual service, not just as a safety check, but also to ensure your boiler is in peak condition. It is also a requirement to maintain the boiler to fulfil both the manufacturer’s warranty obligations and our own warranty on your heating system.

What you should expect from your service:

- Checks for corrosion and leaks.

- Checking all the main components of your boiler are working properly.

- A gas pressure check.

- A flue test.

- A clean of any parts that need it.

- A completed checklist of all relevant information.

Repressurising your hot water cylinder

Repressurising your hot water cylinder is quite simple. Here’s how:

- Turn off your boiler.

- Find the red expansion chamber at eye level, attached to the wall near the cylinder.

- Find the chrome valves with black taps below the chamber. Turn the taps at 90 degrees across the pipes. If the braided flexible pipe (filling loop) is attached to both valves, go to point six.

- Remove the two chrome ‘blanks’ on the valve outlets, turn anti-clockwise to loosen.

- Find the filling loop attached to, or next to, one or both valve ends. Attach it to both valve ends by turning the end connectors clockwise until they are tight.

- Turn the black valve closest to the pressure gauge so it’s in line with the pipe.

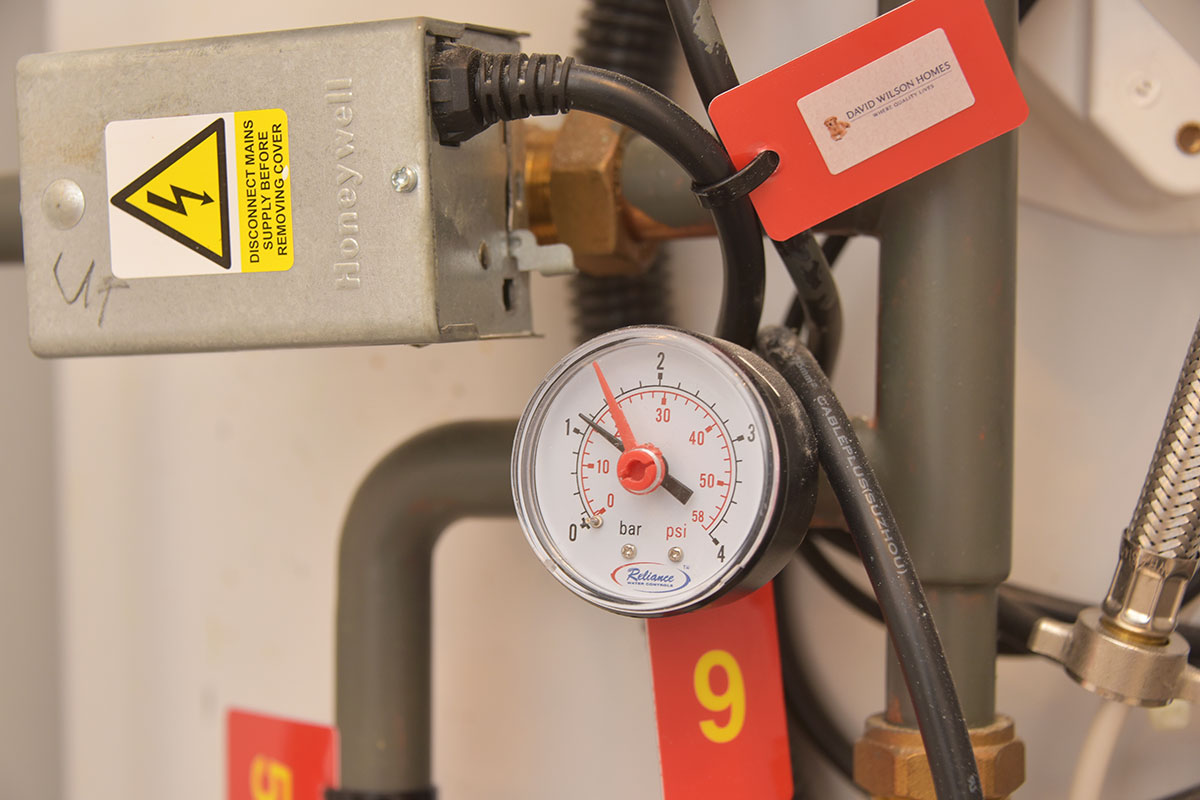

- Turn the black handle on the other end through 90 degrees, constantly checking the needle on the pressure gauge, as you’re now repressurising your system. When it’s between 1.0 and 2.0 bars (1.5 is ideal), turn the valve handle back to its original position.

- Repeat with the right-hand valve.

- Turn the boiler back on. Remove the filling loop and replace the caps.

Combi boiler system

Servicing a combi boiler

Combi boilers are a great way to heat your home and they’ll also need that annual service from a Gas Safe-registered engineer.

What you should expect from your service:

- A visual inspection to check all safety standards and regulations are followed.

- A ‘firing test’ to ensure everything’s functioning properly.

- The flue is checked to ensure it’s working properly and isn’t blocked.

- The flue gas is monitored for carbon monoxide.

- The main parts are cleaned and any damaged components are repaired or replaced.

- Internal components are inspected.

- A completed service report with details of the work.

Repressurising your combi boiler

If your combi boiler loses pressure it’ll be less efficient and may not function properly. There’s a pressure gauge in the control panel under the boiler; if it’s below the 1.0 bar you’ll need to repressurise.

It’s simple to do, just follow these instructions.

- Turn off the boiler.

- Find the chrome valves with black taps under the boiler, one on a pipe just off centre and the other on a pipe dropping from the boiler to the right. Ensure the taps are at 90 degrees to the pipe. If the braided flexible pipe is attached to both valves, go to point five.

- Remove the two chrome ‘blanks’ from the valve outlets, turning anti-clockwise to loosen.

- Find the braided, flexible pipe (filling loop) next to the boiler. Attach this to both valves by tightening the end connectors clockwise.

- Keep turning until they are tight.

- Turn the black valve on the right-hand valve 90 degrees so the handle is in line with the pipe.

- Turn the black handle on the left-hand valve through 90 degrees. Check the pressure gauge, as you’re now repressurising the system. Keep going until the pressure is between 1.0 and 2.0 bars (1.5 is ideal). At this point, turn the valve handle back. Likewise with the right valve.

- Turn the heating back on and remove the filling loop.

If you need to repressurise more than once in a three-month period, there may be a leak.

Your heating system and your warranty

To ensure your two year warranty remains valid, you must service your air source heat pump, boiler, unvented hot water system (cylinder) and solar panels annually and/or in accordance with the manufacturer’s recommendations. You can do this either via the manufacturer or an independent fully qualified plumber of electrician (depending on the system installed). For traditional gas fuelled heating systems, the contractor must be Gas Safe Registered.

Keeping a record of the service history will ensure that your two year warranty remains valid. If you do not service your heating system in accordance with the manufacturer’s recommendations, this will render your warranty for these appliances as null and void.

Please note that not all service providers are able to undertake a full service to an unvented hot water system, please do ensure that your attending engineer is appropriately qualified to provide this service.

Caring for your district heating

With district heating there is no need for annual safety checks on your HIU (heat interface unit).

Emergency

Our teams are on hand when you need us, especially in the event of an emergency.

Get in touch

The New Home Customer Care Team is available via email.